Your number one tooling source

for over 30 years

ISO 9001 Certified

Innovative solutions, at your service

One Source Group has over 30 years of experience in the tool and die industry. Our commitment to innovation and quality has allowed us to stay up front in the ever-changing tooling world. Our wide range of capabilities and dedication to service shows true in our work. Our Southern Ontario plant operates 24/7 with 45 plus employees.

One Source Group has built strong relationships with many companies overseas, giving us the capabilities to explore new avenues and build our tooling network. With relations in China, Japan, Germany, South Korea, Portugal and our partners in the USA we are able to build a strong brand for the future.

Operating in Wallaceburg, ON for 35 years.

Our focus on quality plastic injection tooling has allowed One Source to grow from a small eight man shop in the mid 80’s to a global tooling supplier today. With business connections in the Southern US and overseas, One Source continues to stay on top of the ever changing tooling world.

View MoreA competitive full service supplier in Gadsden, AL.

With over 35 years of tooling knowledge MS-2 is dedicated to providing service in a professional and on time manner. Our new facility has the capabilities to handle a variety of tool sizes, and our staff is ready to serve you 24/7 for all your tooling needs.

View MoreServices we offer for the

tooling and molding industry

Tata Air Intake System

Lead innovator in the new plastic product

development for Tata Air Intake System.

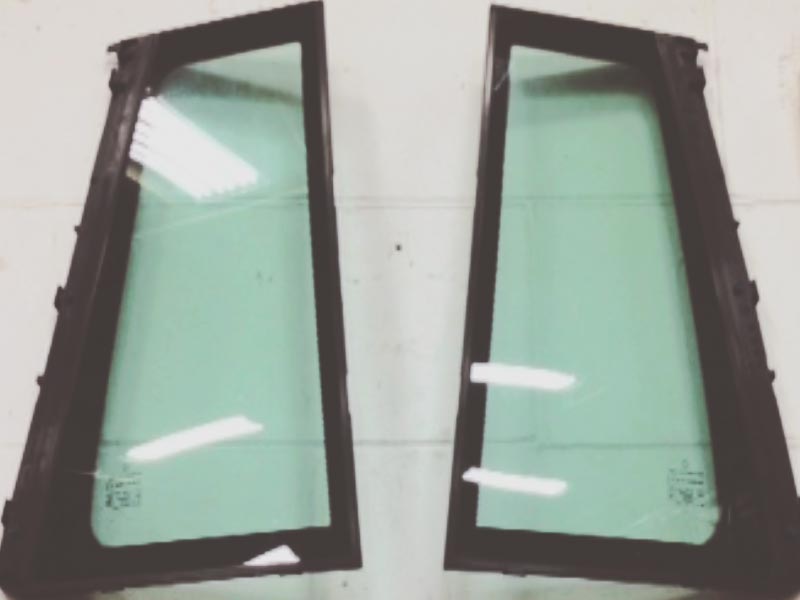

Our 2 shot Dodge Ram tool running at 1 Source Design

One Source was instrumental in assisting Dodge for their 2009 Ram pickup truck. The 2 shot dash panel tool was designed, built and molded in Wallaceburg, ON in a 5 month time frame.

Whats New

1 Source Design is continuing to grow and meet machining and tooling demands. This is our 3rd Toshiba Boring Mill that will go into operation this November. This CNC machine will work around the clock speeding up tool builds and opening up new avenues for us. Contact our sales team anytime for machine rates and availability.

Machine Specs

- Spindle - 6 inch, X - 160", Y - 120", Z - 60"

Die Casting

One Source is continuing to raise the bar when it comes to die cast tool building. Our knowledgeable design team and skilled toolmakers give us a step up in the die cast game. Our latest project has us tackling a 55,000lbs tool in house from the design stage, to build, to molding production. Check back soon for more details and reach out to us anytime.

Repairs and Maintenance

- One Source also specializes in manufacturing complete sets of replacement inserts for existing die cast dies.